Contributing to the significant trade with the world, the Indian textile industry alone excels in the domain. From the ancient civilizations to mediaeval, modern and postmodern sections of history, textile finds their due in creative accolades and bringing the world together. Weaving yarns of yesterday; for a unity fabric of today, spinning the wheel of time and loom. It is through this textile journey that we culture the timeless pieces we grace on our bodies. Celebrating such a rich heritage of textiles, we knit into the diversity of Gujarat textile design.

An exquisite state, an important port, and a facilitating trade route since the Indus civilization period; Gujrat holds dominance when it comes to Textile design manufacturing and export. The primary centres of the state are: – Ahmedabad, Surat, Rajkot, and Vadodara. Besides the city hubs, the smaller towns of Bhuj, Patan and Bhavnagar also convey their share in the Gujarat textile design community. Specified below are the lustrous textiles and their originating areas.

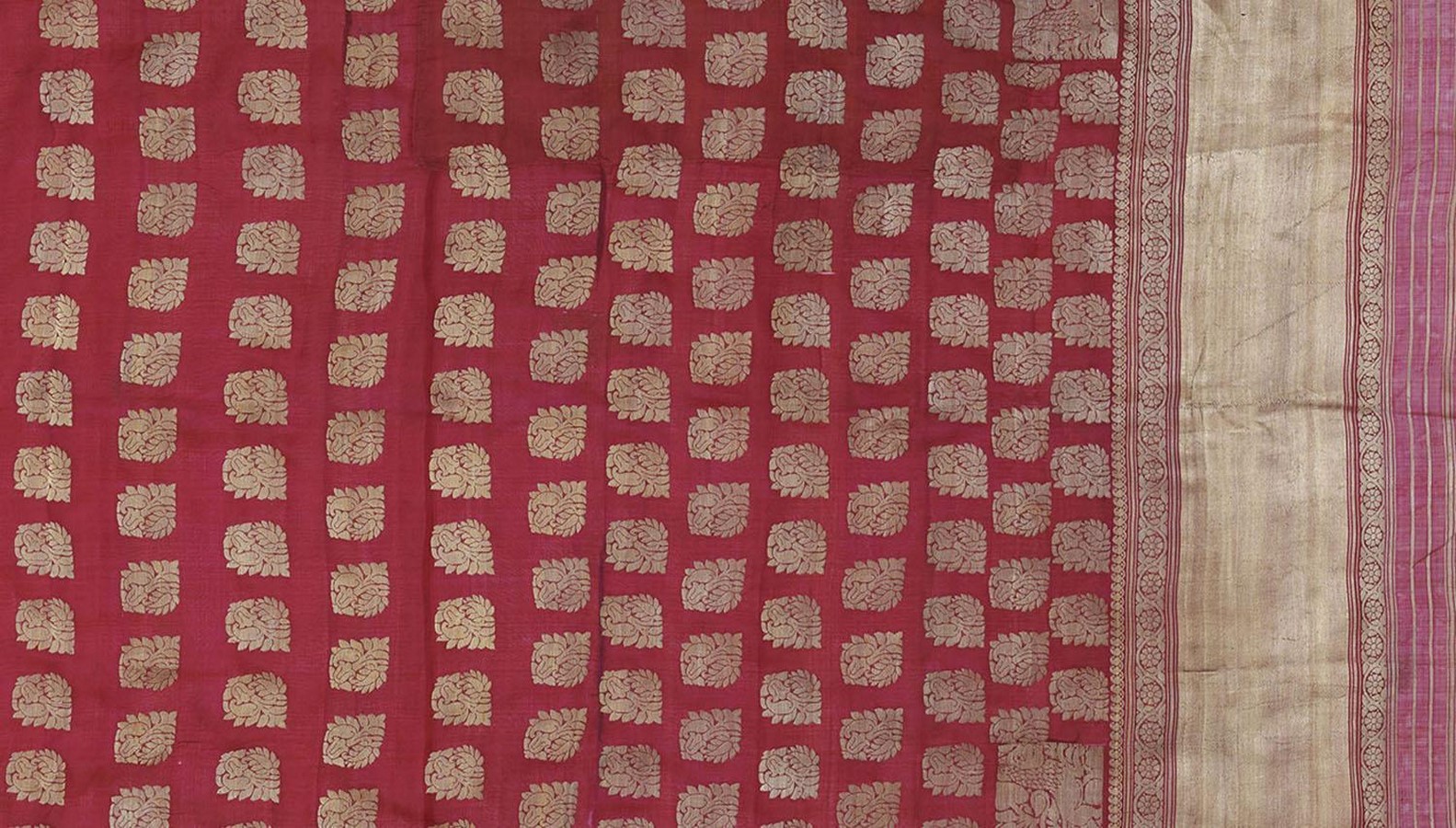

Ashavali fabric – Ahmedabad

The present-day Ahmedabad city stands in the yesteryear area of settlements of Ashvals. From the Ashavals came the rich silk brocade fabrics. They are made of twill weave such that motifs appear a bit embossed. They are woven with extra Zari (gold and silver thread) as a weft. In contrasting colours, the main motifs are of flora fauna, Paisley/Ambiya (mango-shaped), Jalis and deities. Out of all motifs, the Chand Taara motif (moon and star) is the most printed feature of the textile for the borders of the textiles. These textiles are known to retain the shine of silk, as they are always enamelled and exhibit bright hues even though they are naturally dyed.

Patola – Patan

The Patola fabric has been a renowned trademark and synonymous with Gujarat for ages. This art of the Salvi community made its way to Gujarat from Maharashtra. It is an intricate woven fabric which utilises the already dyed thread into warp and weft. This process of dying the thread before weaving is known as Ikat. Patola uses two yarn threads which are dyed, therefore making it a double ikat weave. Produced on tilted looms, the area is now a leading manufacturer of the world-famous Patola sarees. The warp and weft are interlocked according to the pattern desired and knotted at intervals. On applying the dye, these knots resist the dye and create voids, which result in a pattern. The Patola fabrics give enchanting geometric patterns along with some motifs (locally called Bhat) of parrots, humans, flowers and animals. Owing to its tedious manufacturing, the Patola fabrics are one of the most expensive pieces in the Gujarat textile design.

Bandhani /Bandhej from Surat

The resist dyeing technique of cotton and silk fabrics; which is first washed and bleached is the Bandhej pattern. The patterns on the cloth are mirroring ones, hence they are tied /folded into four symmetrical parts. The pattern making takes place by creating dots with the design and simply tying it with a cotton thread. The final process of dying is after pattern making and thread tying. The fabric is then subjected to subsequent washes and starching. The final finished product is shown after releasing the threads, which results in an emerging pattern with white dots and the rest of the fabric dyed in beautiful colours.

Ajrakh Print- Kutch, Ajrakhpur

The word Ajrakh is coined from two different words, Aj (today) and Rakh( to keep). Some also say it is derived from Azrak (Arabic for Blue). The Ajrakh printing technique usually involves printing on both sides using wooden blocks. It is usually a resist-dyeing method. The tradition of Ajrakh came from Sindh (Pakistan) to Gujarat through the Khatri community. The cloth is washed and dyed using colours, mostly blue and black. The first process called ‘kasanu ‘involves dyeing fabric with yellow colour (Harda). After drying, the craftsman prints a resist using lime and natural gum on the fabric. The resist known as rekh is applied on both sides, making the lines resistant to alizarin and indigo, resulting in a white finished product. Printing lines using a dye consisting of iron, jaggery, millet, and tamarind is a traditional Indian textile method. The lines turn black due to oxidising in the air. To fill in red details, alum is employed as a mordant. To prevent indigo bleeding, a paste known as pa is applied. The cloth is then coloured green and blue in big vats of indigo, lime, jaggery, and mustard seeds. After washing and drying, the cloth is transformed into a shape known as minakari. Sheesham, rohida, and sagwan wood blocks are carved drawing inspiration from cosmic and natural themes. The geometric patterns printed on the cloth take inspiration from architectural features like Jalis and arches too.

Embroideries on Cloth

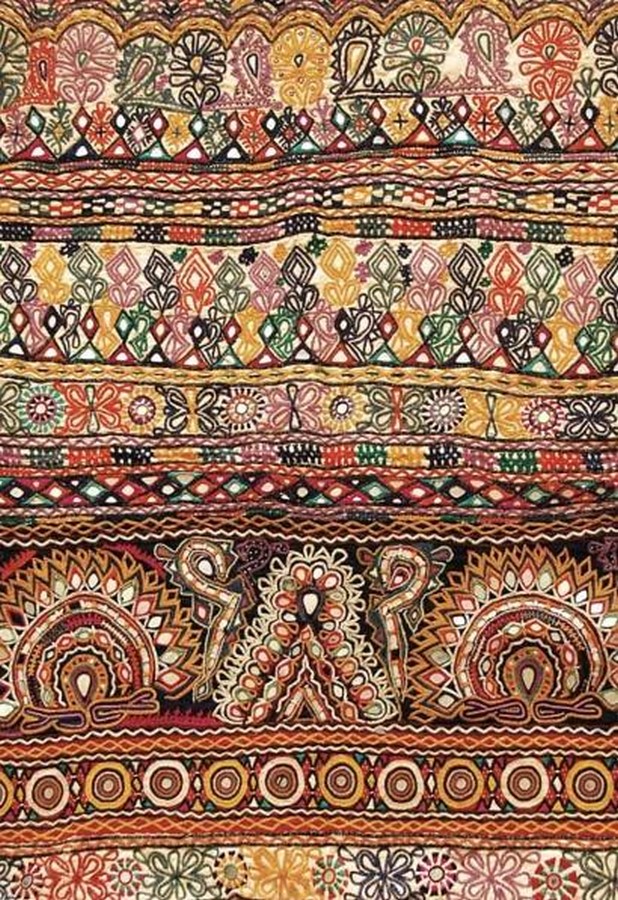

Coming forth as a prominent centre of embroidery and needlework using silk/woollen threads, Kutch has a stronghold. With the advent of trade and displacement from Iraq, Iran and Afghanistan, the embroidery styles evolved eventually. Many communities practise embroidery work in the Kutch and nearby regions. Some of them are Aari embroidery, Rabari embroidery, Sindh embroidery, Abla/Abhala, Zari art and Katab/Applique work.

Aari embroidery (Bhavnagar): Aari is a Hindi word for an awl. It is said that these embroideries were done by the mochi community on leather shoes and bags. It is done in fine pace and texture, almost like a thin crochet style. Small stitches make a large part of the embroidery look. Common motifs formed through stitches include those of parrots, peacocks, flowers, and a lady standing with flowers.

Zari Ari–Surat: It is one of the oldest handicrafts using metal thread embroidery. Dabka(flattened, metal threads twisted around silk threads) are used for this technique of embroidery. This work is generally associated with floral patterns, it is also used with Bandhani to give fabric a beautiful look. Jamnagar, Mandavi and Bhuj are major districts producing this embroidery.

Rabari embroidery: The leading community carrying the master craftsmanship of this embroidery is the Rabari community, hence the embroidery name. Most of the workforce is women who beautifully work on the technique of chain stitches with their expertise.

Kathiawar embroidery: The embroidery is somewhat like that of the other chain stitch-inspired embroidery, but the motifs are different. Kathiwar gets its name from Kathi’s landlord caste and practitioners of the Khalipa style of embroidery. Legend has it that Lord Krishna killed Jara Singh and rescued 1600 ladies, later marrying them out of respect. As a token of love, the ladies gave in to their style of embroidery and presented it to Lord Krishna. These embroideries were later combined and named Kathiawar embroidery. It is used by the community to design torans and other embroidered panels. Some of it also makes use of tiny mirrors(shisha) in the designs.

Sindh Embroidery: It utilises the interlacement stitch (Maltese square). The embroidery originates from Baluchistan, but with trade and migration of communities, it is now practised in Gujarat. The major districts producing this embroidery are Khaipur and Mirkhapur. The basic skeleton structure is made with long stitches and then together, they form geometrical patterns or simply borders. It is also carried out in combination with Abhla(mirror work). All stitches are attached with herringbone stitches, especially for the mirror periphery. The clothes show exuberant colours like maroon, yellow, and red and dark colours like black.

Abla/Abhala: It is done by the Banjara community. Shiny floss threads are used for mirror work. The prime stitches are chain stitch and herringbone with some influence of Kutch embroidery. It is done on Ghagra cholis, blouses, chakla etc. The colours used are bright colours, such as indigo, blue, red, pink and yellow, green and orange.

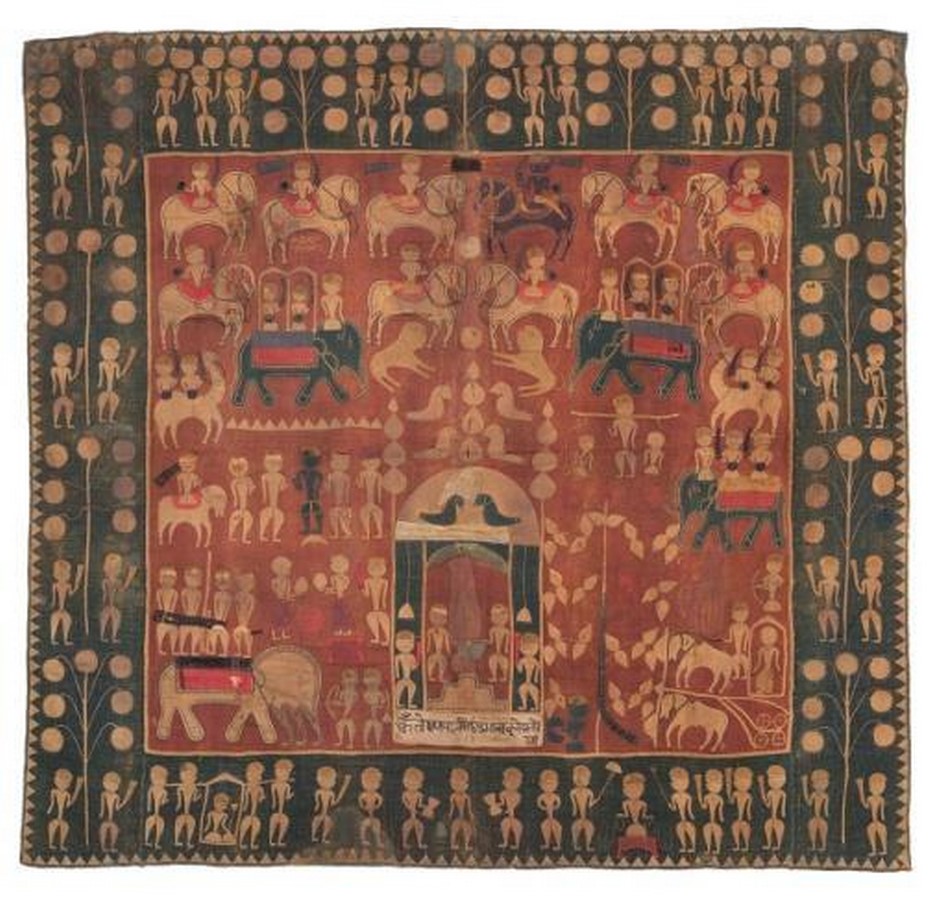

Katab/Appliqué: It is practised by women of Meghwal, Rabari and Mahajan communities. Modern-day katab artisans are those who travelled from Pakistan during the partition. It is based in Vadodara, Rajkot and Ahmedabad. Katab is a historic weaving technique for fabric appliqué that uses surplus cloth. Cutting the cloth into certain shapes, assembling them according to a design, and positioning many pieces together are all part of the process. The created patterns typically have symmetrical, geometric, or floral shapes and can be accentuated with Ajrakh prints.

Bhujodi weave- Bhuj district

The weave is foremost practised by the Vankar community. The community specialised in weaving shawls and woollens for Rabari hearers in Kutch. Bright colours of shawls, blankets and carpets. Chaumukh, Sathkhani and Dongla are woven on fabrics.

Thangaliya weave- Surendranagar

The Thangaliya weave is a one-of-a-kind fabric, woven with composure by the Dangaish community. It is the art of weaving in the beads (Danas) on the warp or weft of the fabric. Warp threads are selected according to the design and tiny dots of thread are twisted and knotted around those beads thus creating intricate patterns on the fabric.

Conclusion

The weaving community of Gujrat exemplifies what a self-sufficient community and their coexistence can bring to the craft. The communities have so far indulged in sustainability for ages and produce goods with meticulous crafting. They are the epitome of bringing tangible to the intangible. The Rabbari community wearing products worked by the Vankar community is a living testimony of the roots of culture and community co-living with a sense of collective empowerment. One can see this as safeguarding practices and still rising above hierarchical curses. Equality in produce and monetary independence for years have further strengthened the Gujarat textile design. The manufacturing market thus creates opportunities for them to make their own decisions as they practise a tradition of being a sole stakeholder in it. The question here is! What is the community relying on these traders and craftsmen doing to promote the element of cohesivity and delving into the culture tied together by these master artisans? In the end, it just comes across as clothing their bodies but not their hideous souls.

References:

- Articles are written collaboratively by the EIA editors. More information on our team and FILED UNDER Textiles (2023a) Ajrakh, MAP Academy. Available at: https://mapacademy.io/article/ajrakh/ (Accessed: 15 October 2023).

- Articles are written collaboratively by the EIA editors. More information on our team and FILED UNDER Textiles (2023b) Katab appliqué, MAP Academy. Available at: https://mapacademy.io/article/katab-applique/ (Accessed: 15 October 2023).

- Chain, T.V. (2021) Textiles of Gujarat, Textile Magazine, Textile News, Apparel News, Fashion News. Available at: https://textilevaluechain.in/in-depth-analysis/articles/traditional-textiles/textiles-of-gujarat/ (Accessed: 15 October 2023).

- Textiles of Gujarat (no date) INDIAN CULTURE. Available at: https://indianculture.gov.in/node/2787199 (Accessed: 15 October 2023).