3D printing is a technology that uses overlapping layers of material to create a tangible model from digital information. Using softwares like CAD, Revit, and Rhino, 3D printing is becoming an everyday tool for architects and designers to visualize their creations in an effective, precise, and swift way. From small study models to large-scale, intricate, and detailed ones, different machines help with creating variations in the modeling and building process. 3D printing is a vast field dealing with numerous materials and technologies matching the needs of various purposes of designs.

History of 3D printing

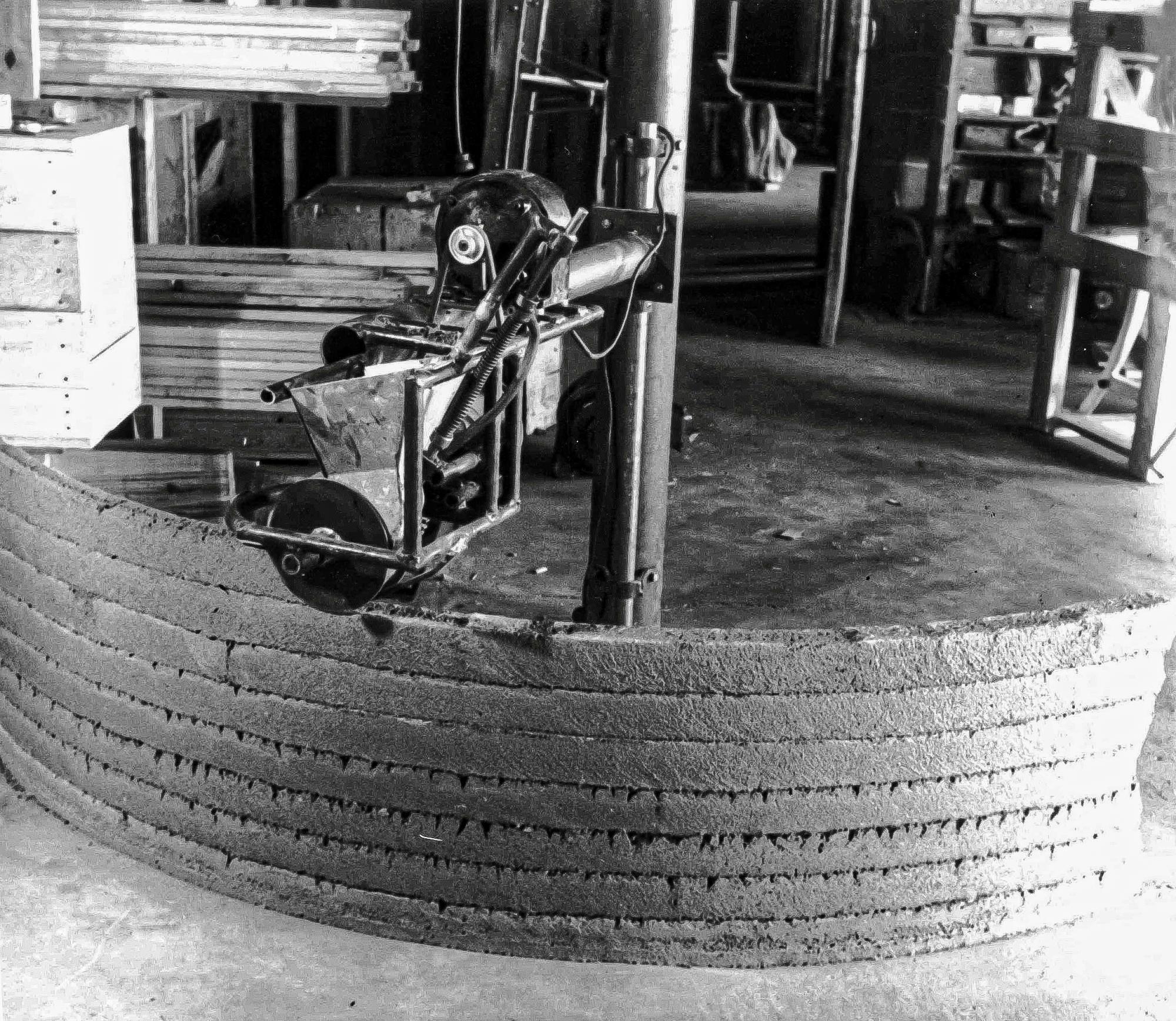

In 1939, Willian E. Urschel created the first ever 3D-printed concrete structure at the back of a small warehouse in Indiana, United States. His invention called the “Wall Building Machine,” consisted of an automatic ramming mechanism that compressed concrete between spinning disks, consolidating and smoothing each layer as the material was extruded. Urschel filed a series of patents for his “Wall Building Machine” in 1940. The machine would be used to fabricate multistorey structures with integrated reinforcement and self-supporting domes, all printed in concrete without formwork.

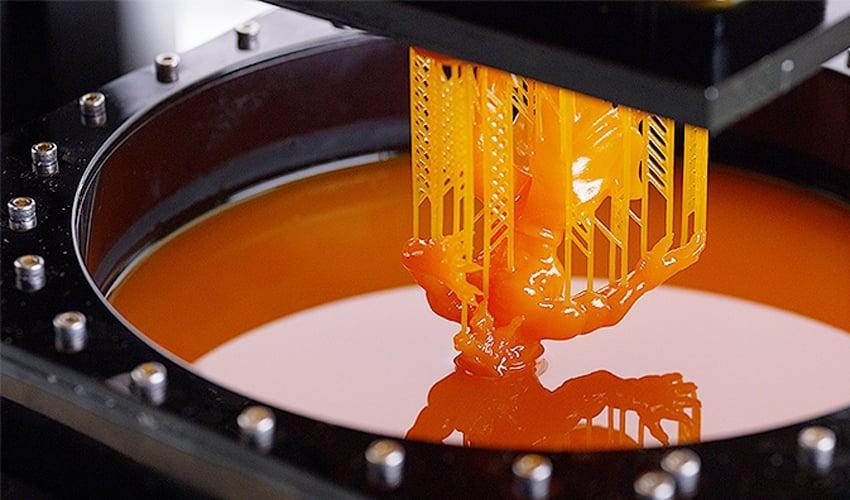

In the 1980s, Hideo Kodama of Japan was in the process of developing a quick prototyping method. He invented a technique that used layer-by-layer manufacturing of the model using photosensitive resin polymerized by UV radiation. Charles Hull created the first ever stereolithography (SLA) 3D printer in 1988 by curing photosensitive resins with radiation, lasers, or particles. The printer worked by curing or hardening the photosensitive resin layer by layer to form a three-dimensional object. Hull patented his printer in 1986 under the name “Hull’s Stereolithograph.” The STL file format that is used commonly in 3D printing software was born alongside. Carl Deckard holds the patent for the SLS process for 3D printing, and Scott Crump patented Fused Deposition Modeling (FDM).

3D printers for architectural models

Depending on the complexity of the details of the structure, a specific printing technology is selected. The popular ones used widely by architectural firms are:

- Stereolithography (SLA)

SLA parts offer the highest resolution and precision of any plastic 3D printing technology. SLA parts have the smoothest finish and are easy to paint. SLA proves to be an excellent option for creating intricate presentation models. It is also the fastest 3D printing process for most parts, using materials like Draft Resin. Architects and model makers may manufacture really large-scale models with large-format 3D printers like the Form 3L, even if desktop SLA printers have a more compact build capacity.

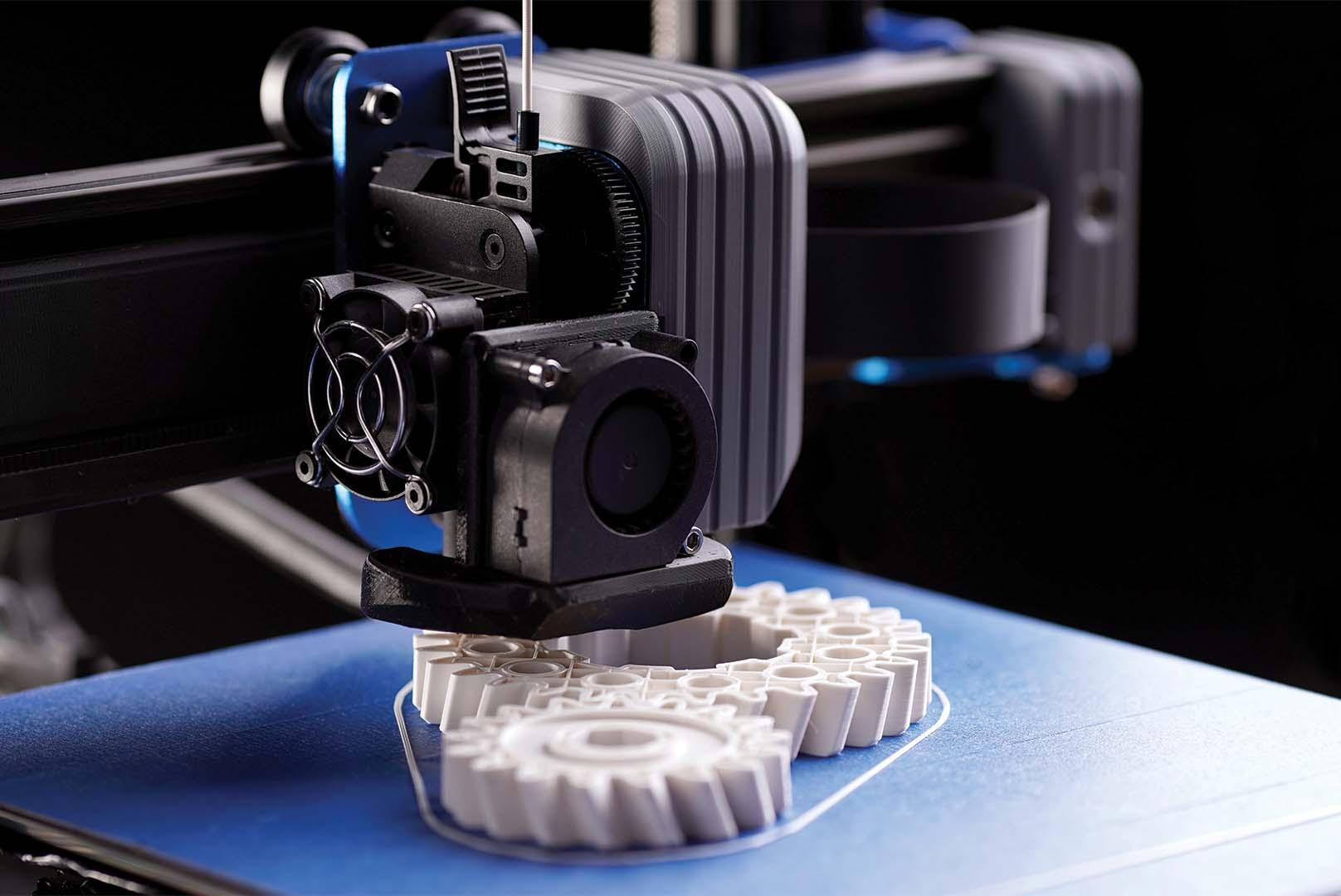

- Fused Deposition Modeling (FDM)

Fused deposition modeling (FDM), also named fused filament fabrication (FFF), is a widely used form of 3D printing by architects for study models. These printers fabricate parts by melting and extruding thermoplastic filament, which a printer nozzle arranges layer by layer in the build area. FDM gives the lowest resolution and accuracy; it can create large models rapidly and at a low cost.

- Selective Laser Sintering (SLS)

Selective laser sintering 3D printers use a high-powered laser to bind small particles of polymer powder. It is the most commonly used additive manufacturing technology for industrial applications. Complex geometries, such as internal features, undercuts, thin walls, and negative features, are best suited for SLS printing. With superior mechanical qualities, parts made with SLS printers can also be used as structural parts.

- Binder Jetting

Binder jetting 3D printing technology is related to SLS printing; it uses a colored binding agent to fuse powdered sandstone material instead of heat. Binder jetting printers can produce colored 3D architecture models. Parts created using binder jetting have a porous surface and are very brittle. The process is recommended primarily for static applications.

3D printing for sustainable architectural practices

3D printing isn’t 100% eco-friendly, but it showcases environmental benefits compared to conventional methods. The printer uses the exact amount of concrete needed to fabricate the physical model and uses less material by printing hollow walls. Formwork is eliminated, leading to minimal construction waste. Sustainable, renewable, and organic materials like raw earth, mud, and bamboo composite can be used to develop compact homes. Printed buildings can, therefore, significantly lower their carbon footprint by using fewer materials, producing less waste, requiring less transportation, and possibly utilizing natural or recycled materials.

Case study: House Zero by Lake Flato Architects

Built in 2022 in Texas, the first project in ICON’s “Exploration Series” aims to “shift the paradigm of homebuilding” by bringing into the limelight the architectural possibilities using additive manufacturing to create new design experiments. The materials of the house create a juxtaposition of robotic construction methods and the textures of natural wood. The 3D-printed wall components are built in ten days, and the total area of the walls is 2000 square feet (186 square meters).

Steel reinforcement and a unique ICON material called Lavacrete, which resembles cement and improves insulation while remaining airtight, are used to cover the walls. The fluid curves of the 3D-printed support walls create “naturalistic circulation routes throughout the home,” according to ICON, which states that the home was built using biophilic design principles. Apart from expediting the construction process, technological advancements may also result in more affordable housing for this type of home.

3D printing for the present and future

With promising developments in the field of invention of materials and technologies dealing with 3D printing, the future holds tremendous potential. 3D printing helps create accurate models and assemble on-site structures, saving time, money, and materials. The cost of labor is minimized. The housing shortage can be provided with solutions using rational and feasible designs. With the world facing constant conflicts, 3D printing can be effectively used to create modules for affected civilians to help them relocate and rehabilitate. Architects play a crucial role in society, and 3D printing can be unleashed as a powerful tool to help create better and more sustainable environments in the future.

References

- Online sources

Citations for websites:

Koumari, L. (2022). 3D-Printing in Architecture. [online] ParametricArchitecture. Available at: https://parametric-architecture.com/3d-printing-in-architecture/ [Accessed 5 Nov. 2023].

Formlabs. (n.d.). Guide to 3D Printing Architectural Models. [online] Available at: https://formlabs.com/asia/blog/3d-printing-architectural-models/ [Accessed 5 Nov. 2023].

Montjoy, V. (2023). Infographic: the Evolution of 3D Printing in Architecture, since 1939. [online] ArchDaily. Available at: https://www.archdaily.com/1005043/infographic-the-evolution-of-3d-printing-in-architecture-since-1939 [Accessed 5 Nov. 2023].

Montjoy, V. (2022). Towards Sustainable and Affordable Housing: Is 3D Printing the Future or the Present? [online] ArchDaily. Available at: https://www.archdaily.com/979103/towards-sustainable-and-affordable-housing-is-3d-printing-the-future-or-the-present [Accessed 5 Nov. 2023].

- Images/visual mediums

Citations for images/photographs – Print or Online:

Ikiz, S.U. (2022). 3D-printed Cement ‘Bloom’ Pavilion Created by Emerging Objects. [online] Parametric Architecture. Available at: https://parametric-architecture.com/emerging-objects-created-a-3d-printed-cement-bloom-pavilion/ [Accessed 5 Nov. 2023].

Perez, B. (2022). 3D Printed Houses Are Much, Much Older than You Think. [online] 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Available at: https://3dprint.com/296046/3d-printed-houses-are-much-much-older-than-you-think/ [Accessed 5 Nov. 2023].

P, A. (2022). The Complete Guide to Stereolithography (SLA) in 3D Printing. [online] 3Dnatives. Available at: https://www.3dnatives.com/en/stereolithography-explained100420174/# [Accessed 5 Nov. 2023].

bmxlovesk.xyz. (n.d.). 42963715 – Online Store. [online] Available at: https://bmxlovesk.xyz/product_details/42963715.html [Accessed 5 Nov. 2023].

3DPrintingNews (2012). Complex architectural model created in SLS | 3D Printing News. [online] 3dprintingnews.co.uk. Available at: http://www.3dprintingnews.co.uk/selective_laser_sintering/loire-valleys-largest-chateau-recreated-in-sls/ [Accessed 5 Nov. 2023].

Hubs. (n.d.). How to Design Parts for Binder Jetting 3D Printing. [online] Available at: https://www.hubs.com/knowledge-base/how-design-parts-binder-jetting-3d-printing/ [Accessed 5 Nov. 2023].

Short, S. (2022). Building Sustainable Housing: Is an Eco-Friendly Future 3D Printed? –. [online] Christie’s International Real Estate. Available at: https://www.christiesrealestate.com/blog/building-sustainable-housing-is-an-eco-friendly-future-3d-printed/ [Accessed 5 Nov. 2023].

PourMohammadi, H. (2023). 3D Printing in Construction: 6 Examples and Case Studies – Neuroject. [online] neuroject.com. Available at: https://neuroject.com/3d-printing-in-construction/ [Accessed 5 Nov. 2023].